35% of companies adopting Industry 4.0 predict revenue gains over 20% in the next five years.

35% of companies adopting Industry 4.0 predict revenue gains over 20% in the next five years.- Data analytics and digital trust are the foundations of Industry 4.0.

- Cost-sensitive industries including semiconductors, electronics, and oil and gas are the most focused on adopting Industry 4.0, with 80% of companies in these industries saying it is one of their top priorities.

The recent article by Boston Consulting Group (BCG), Sprinting To Value In Industry 4.0, provides insights into how real-time integration between enterprise systems is an essential catalyst for Industry 4.0 growth. Industry 4.0 focuses on the end-to-end digitization of all physical assets and integration into digital ecosystems with value chain partners encompassing a broad spectrum of technologies. BCG surveyed 380 US-based manufacturing executives and managers at companies representing a wide range of sizes in various industries to complete the study.

Industry 4.0 Is At An Inflection Point Today

Having attained initial results from Industry 4.0 initiatives, many manufacturers are moving forward with the advanced analytics and Big Data-related projects that are based on real-time integration between CRM, ERP, 3rd party and legacy systems. A recent Price Waterhouse Coopers (PwC) study of Industry 4.0 adoption, Industry 4.0: Building The Digital Enterprise (PDF, no opt-in, 36 pp.) found that 72% of manufacturing enterprises predict their use of data analytics will substantially improve customer relationships and customer intelligence along the product life cycle. Real-time integration enables manufacturers to more effectively serve their customers, communicate with suppliers, and manage distribution channels. Of the many innovative start-ups taking on the complex challenges of integrating cloud and on-premise systems to streamline revenue-generating business processes, enosiX shows potential to bridge legacy ERP and cloud-based CRM systems quickly and deliver results.

There are many more potential benefits to adopting Industry 4.0 for those enterprises who choose to create and continually strengthen real-time integration links across the global operations. Recent research completed by Boston Consulting Group and PwC highlight several of them below:

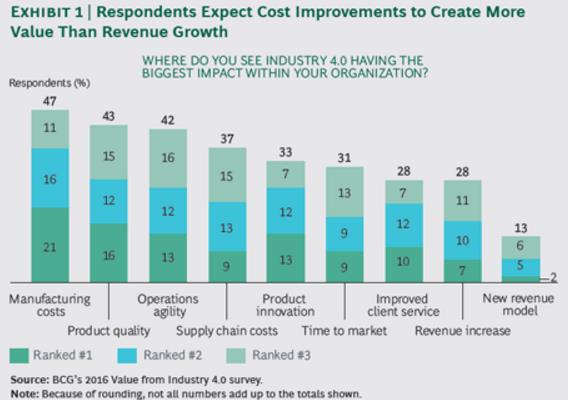

- Manufacturers expect to gain the greatest value from Industry 4.0 by reducing manufacturing costs (47%), improving product quality (43%) and attaining operations agility (42%). 89% of all manufacturers see an opportunity to use Industry 4.0 to improve manufacturing productivity. Reducing supply chain costs (37%), enabling product innovation (33%) and attaining faster time-to-market (31%) are the next level of benefits manufacturers expect to attain. The following graphic provides an analysis of where manufacturers see Industry 4.0 having the greatest impact on their organizations.

- Manufacturers are gaining the greatest value from Industry 4.0 by creating pilot projects that create flexible, agile real-time platforms supporting new business models with real-time integration. Industry 4.0’s focus on enabling end-to-end digitization of all physical assets and integration into digital ecosystems relies on real-time integration to succeed. For manufacturers in cost-sensitive industries, the urgency of translating the vision of digital transformation into results is key to their future growth. The more competitively intense an industry, the more essential real-time integration

- Investing in greater digitization and support for enterprise-wide integration is predicted to increase 118% by 2020 in support of Industry 4.0. 33% of manufacturers surveyed report they have a high level of digitization today, projected to increase to 72% by 2020. The leading areas of these investments include vertical value chain integration (72%), product development and engineering (71%), and customer access including sales channels and marketing (68%).

- New product development and optimizing existing products and services are the greatest areas of growth potential for analytics and Big Data using Industry 4.0 technologies and integration strategies through 2020. Industry 4.0 is revolutionizing the use of analytics and manufacturing intelligence, setting the foundation for greater optimization of overall business and control, better manufacturing, and operations planning, greater optimization of logistics and more efficient maintenance of production assets and machinery. By better orchestrating these strategic areas, manufacturers are going to be able to attain levels of accuracy and responsiveness to customers not achievable before.

- Globally, manufacturing enterprises expect to gain an additional 2.9% in digital revenues per year through 2020, with digitizing their existing product portfolios (47%) leading all other strategies, further underscoring the need for real-time integration. Introducing an entirely new digital product portfolio is the second most common strategy (44%) followed by creating and offering new digital services to external customers (42%). Just over a third (38%) plan to create and sell big data analytics services to external customers.