QAD | Redzone is looking to infuse AI, process intelligence and frontline worker empowerment as it looks be the ERP provider of choice for mid-market manufacturing companies. The goal: Provide the systems that reinvent manufacturing.

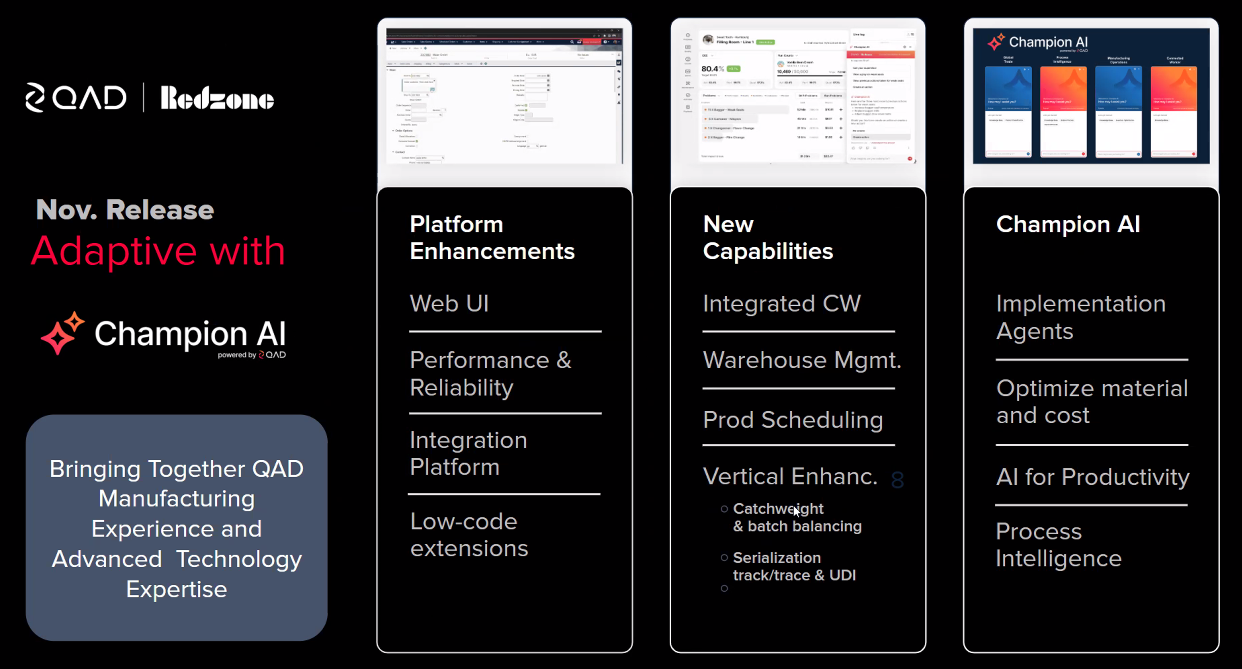

The company launched its next generation ERP platform, QAD Adaptive powered by Champion AI, an agentic AI engine that's designed to turn manufacturing systems of record and make them actionable. Those efforts complement Redzone Connected Workforce, which aims to bring process intelligence to frontline workers for better decision-making.

QAD | Redzone's Champion AI is powered by Amazon Web Services and its Amazon Bedrock AgentCore and Amazon SageMaker. As part of the AWS partnership, QAD | Redzone will transition its global IT workloads and internal platforms to AWS. For AWS, the QAD partnership is handy given its push into manufacturing and industrial AI use cases.

AWS CEO Matt Garman said in a statement that the QAD | Redzone partnership is about "moving agentic AI from proof of concept to production" to "incorporate your unique data into workflows."

For QAD | Redzone, the launches are designed to capitalize on a renaissance in manufacturing and the intersection of AI and industrial use cases. The company announced the news at its Champions of Manufacturing event in Dallas.

Sanjay Brahmawar, CEO of QAD | Redzone, said the company is looking to power the next-generation of manufacturing companies that'll be more AI-powered, data driven and nimble. "Manufacturers who lead the next generation of manufacturing will be those that are the most adaptive: turning speed into strategy, data into decisions, and people into catalysts of change. This isn’t just a better version of ERP, it's a new model altogether," said Brahmawar.

Release highlights include:

- Champion AI Agentic Platform, which includes AI agents focused on implementation, productivity and business optimization. The agents are designed to reduce implantation time and deliver value faster.

- A fully embedded Warehouse Management System and enhanced Production Scheduling Model.

- Champion Pace Rapid Implementation, which is designed to streamline and automate implementation tasks.

- Industry-focused enhancements including features for complex manufacturing environments and Unique Device Identification labeling tools to improve supply chain efficiency.

- QAD | Redzone said it has acquired Kavida.ai in a move that will bring AI agents to its procurement and supply chain workflows.

Brahmawar acknowledged that speed to decisions is going to be a critical battleground going forward. The companies that are able to use AI to optimize processes and automate to deliver value quickly will win.

Indeed, Constellation Research analyst Mike Ni said in a recent report that decision velocity will separate winning enterprises from also rans. For manufacturers, which have to deal with tariffs, supply chain shocks and economic volatility, taking data to decision in real-time is everything. "Enterprises have spent billions on data, analytics, and artificial intelligence (AI). The bottleneck and industry focus are no longer technology but decision-making," said Ni in a report. "Decision velocity, defined by how fast and effectively an organization can sense, decide, act, and learn to lift measurable outcomes quickly and accurately is the new yardstick by which boards and CFOs judge AI investments as enterprises move from proofs of concept (POCs) to funded AI initiatives."

A look at the strategy

Brahmawar joined the company in March after serving as CEO of Software AG. In a briefing, Brahmawar walked through the QAD | Redzone strategy. Among the key points:

The manufacturing opportunity. Brahmawar is a manufacturing geek and started his career on a Honda shop floor assembling engines. "QAD was born because the traditional ERP vendors were focused on the wide enterprise," he explained. "They didn't have the depth and attention to everything that happens on the manufacturing shop floor starting from the bill of materials."

QAD | Redzone targets manufacturers with annual revenue between $200 million and $5 billion. In many ways, Brahmawar is bringing QAD back to its manufacturing roots with an ambition to be the best ERP provider for the sector. "I don't want to be everything to everybody. I want to be the best in manufacturing," he said.

Brahmawar said manufacturing is having a watershed moment as governments, countries and multiple geographies see the sector as strategic for national security, economic growth and job creation. QAD's customer base is focused on automotive, food and beverage and discrete manufacturing.

However, there's also a paradox with manufacturing. Capital is flowing into manufacturing and there's not enough capacity as well as an aging workforce. Automation and robotics is capital intensive and rigid. "You can have more productivity and more effectiveness through agentic layers, agentic systems and AI," said Brahmawar. "QAD can create more productivity and also create systems of action that will attract talent to manufacturing."

QAD | Redzone product pillars. Brahmawar said the first pillar for QAD | Redzone is Redzone, which is the company's system for front line workers. "We bring information and data right into the hands of frontline workers," said Brahmawar. The other pillar for QAD is adaptive with an intelligent backbone that's based on process intelligence. And the last pillar is Champion AI, which is AI tools for the manufacturing workforce to increase capacity.

Here's a look at some of the moving parts behind QAD's product pillars and how they play into the manufacturing renaissance.

The data play. Amit Sharma, President of Manufacturing ERP at QAD | Redzone, said one thing to watch in manufacturing is the data behind the value chain with retail, manufacturing and distribution. "The information you have on demand, capacity, planning and availability is going to be much more valuable than the software," said Sharma. "You just need the software to participate.

QAD | Redzone's Champion AI is designed to connect to various data stores, including SAP. Sharma said Champion AI is informed by process intelligence that tells you how your processes are executing today and how they can be improved.

Process intelligence is built into QAD's systems. "Our plan with our ERP is that everything is in one system and providing the intelligence to achieve your KPIs. We have the tools and the means to automate actions with human ability," said Sharma. "That's the vision we are driving toward."

Enabling the frontline manufacturing worker. Ken Fisher, President of Redzone, said QAD's goal with Redzone is to "transform manufacturing by empowering the frontline." According to Fisher, manufacturers that are adaptive will win. Frontline workers are the ones in manufacturing that make the calls. "We provide culture change at scale where operators have ownership. They know what their targets are and what their losses are and they're empowered to do something about it," said Fisher. What Redzone does is connect engineers honing processes directly to the front lines to speed up corrective actions with a data feedback loop tied into the ERP system.

Going forward it's worth watching how QAD | Redzone develops. Manufacturing is the belle of the AI ball and is strategically significant to various countries and regions looking to control their industrial destinies. Simply put, the time to fuse AI, process intelligence and manufacturing systems is now. "For manufacturers, the biggest risk is inaction," said Brahmawar.

Constellation Research analyst Holger Mueller said:

"AI is coming to the shop floor and is likely the biggest transformation of the hand to machine ratio since the introduction of the steam engine. It's good to see that QAD is thinking about the frontline worker in the factory, and providing the platform for the future of work on the shop floor, as enterprises transition from human only to hybrid and likely sooner than later to robot-only shop floors."